SNS Nutrient Reduction Mobile

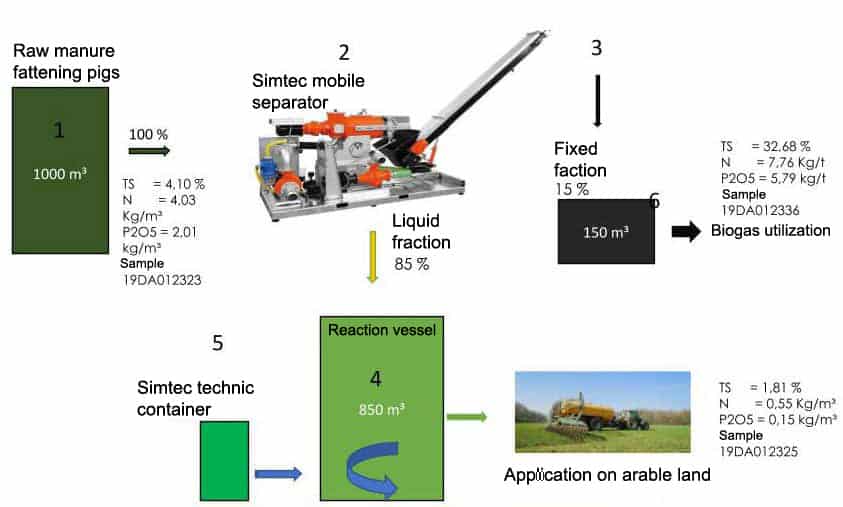

Description Mobile processing plant

1. Raw liquid manure from underground storage in the stables or from a liquid manure storage tank.

2. Simtec mobile press screw separator for separating the raw manure into the solid (3) and liquid (5) fraction.

3. Pressed solid fraction approx. 15% of the raw liquid manure

4. closed reaction tank of an already existing liquid manure storage tank. In this, with the help of the Simtec technology container (5), the nutrient reduction is carried out in an electrochemical process.

5. Simtec Technik Container for the electrochemical process

6. Application from the reaction tank to the arable land after completing the process.

Photos of the SIMTEC mobile separator

Raw slurry: wet pig feeding (RAM)

–

–

Raw manure:

Pig fattening wet feeding (RAM), mushy, thick and lumpy

–

–

1st step:

Start of the reaction, visible through the formation of bubbles

–

–

2nd step:

Increased reaction, blistering and head of foam

End product after passing through the bioreactor

End product:

Pig fattening wet feeding (RAM), homogeneous, thin-bodied

Laboratory results of the end product after passing through the bioreactor

Benefits

- Significant reduction in nutrients in farm manure

- Reduction of nitrogen up to 70% possible

- Conversion of phosphorus up to 90% possible

- no introduction of chemical or other environmentally harmful additives

- no investment costs

- Minimizing the groundwater pollution by nitrate

- high-quality residues as nutrients for the biogas plant (see laboratory report no.4)

- no additional emissions – no hazardous residues

- Reduction of secondary fine dust pollution

- minimum primary energy requirement approx. 1 – 1.5 euros / m³ farmyard manure

- applicable for large and small businesses

Requirements for permanent establishment

- Separation amount per day> 200 m³

- Camp for the thin fraction

- Power connection 32 A 400 volts

- Water connection for cleaning purposes

Mobile implementation

- On-site processing from 200m³ raw manure (pig / cattle manure)

- Cooperation with biogas plant operator for the residues

- Documentation of the substances according to the new fertilizer ordinance

- Immediate implementation

- Optional downstream full processing

Customer opinion

We chose SIMTEC Natural Solution because we run our business in an environmentally conscious way and simply want to save costs.

The SIMTEC module is perfect for my purposes. The setup went very quickly and the employees were able to answer any questions that arose quickly.

The decision in favor of the SIMTEC modules was the right one, because we have found that they reduce operating costs and that we will remain flexible in the future.